Introduction

High capacity, low lift pumps commonly referred to as axial flow pumps are a distinct category within the pump industry. These pumps are particularly sensitive to the conditions at their intake, which has significant implications for their performance and operational reliability. Such pumps are commonly utilised in land drainage and storm water applications.

Classification of High Specific Speed Pumps

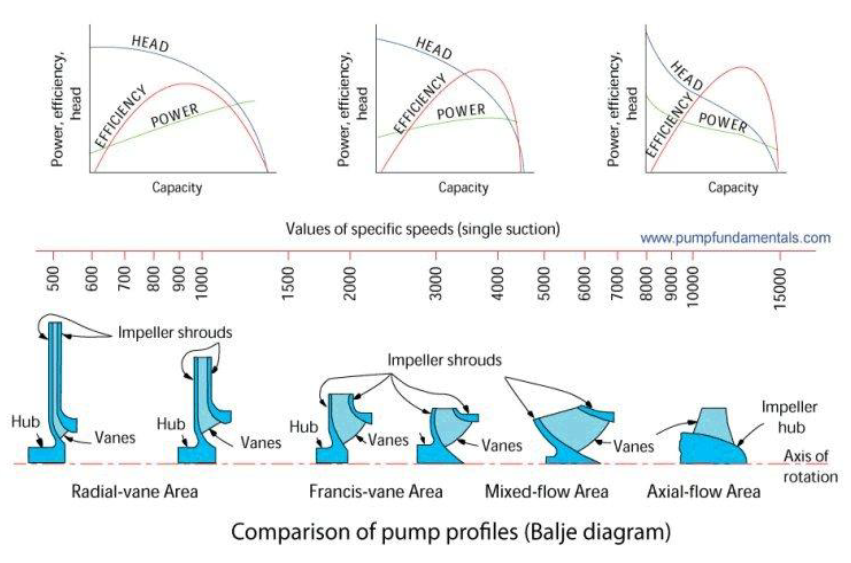

Pump manufacturers typically classify machines according to their specific speed. It is important to recognise that not all high capacity, low lift pumps are pure axial flow designs, as there is a gradual transition from mixed flow to axial flow types. As a rule, the higher the specific speed of a pump the more sensitive it will be to intake conditions.

This should be a key consideration during the design of a new installation and when retrofitting new pumps into existing infrastructure. See below:

Critical Importance of Intake Conditions

While intake conditions influence the performance of all pump types including radial and low specific speed pumps, their importance increases markedly for high specific speed machines. Poor intake hydraulics can result in flow separation, pre-swirl, air entrainment, vibration, noise, and accelerated mechanical wear.

For axial and mixed-flow pumps, ensuring optimal intake conditions is not merely a performance consideration; it is essential for safe and reliable operation.

Intake Structures and Common Hydraulic Phenomena

A number of authoritative references address pump intake design in detail, notably the work of Prosser and the widely adopted industry standard ANSI/HI 9.8: Rotodynamic Pump Intake Design. These publications provide valuable guidance for both new designs and the modification or remediation of existing intakes.

Common hydraulic phenomena encountered in pump intake structures include:

- Pre-swirling liquid or mass rotation

- Vortices both surface and submerged

- Entrained air

- Suboptimal and non-uniform flow velocities

- Insufficient submergence levels

For high specific speed pumps, failure to address these phenomena can lead to adverse outcomes ranging from increased energy consumption and higher maintenance requirements to severe vibration, instability, and, in extreme cases, catastrophic failure.

Challenges in Real-World Applications

Ideal intake environments are rarely encountered in practice. Many pumping stations particularly those associated with land drainage and flood control were constructed decades ago and were not designed to accommodate modern fish safe axial or mixed-flow pumps.

Recent legislation requires many land drainage and water intake pumps to be migratory eel safe. Eel safe pumps tend to be larger and rotate at lower shaft speeds than traditional pumps of equal capacity.

Despite the critical importance of favourable intake conditions, engineers are frequently required to work within the constraints of existing civil structures, limited footprints, and the requirement for uninterrupted operation.

Over the past 12 months, Pumpflow Ltd has encountered a number of such challenges while retrofitting pumps into existing pumping stations. This paper presents practical solutions developed to address these constraints without extensive civil modifications.

Flow Conditioning Solutions

When working within existing infrastructure, opportunities for large-scale structural changes are often limited. In these situations, flow conditioning solutions provide an effective means of improving intake hydraulics.

Flow conditioning typically involves the use of physical devices designed to eliminate turbulence, suppress swirl, and promote a uniform velocity profile at the pump inlet.

- Bespoke bellmouth intakes

- Cruciform flow straighteners

- Formed suction intakes (FSIs)

These solutions are specifically engineered to minimise vortex formation, reduce air entrainment, and stabilise approach flow under a wide range of operating conditions.

Case Studies and Real-World Solutions

The following case studies are real-world examples from recent Pumpflow Ltd projects.

Case Study 1 – Open Gravity Channel Mounting

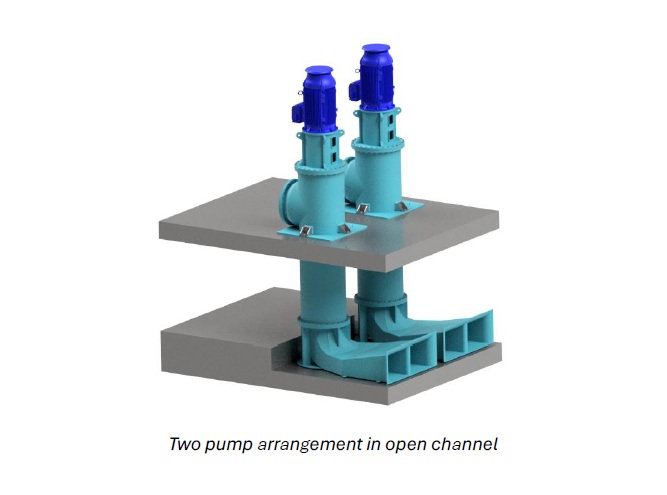

Pumpflow Ltd was commissioned to supply replacement pumps for a land drainage installation where the pumps are suspended directly within an open gravity channel. Due to the operational importance of the station, major civil modifications were not feasible.

This configuration represents one of the most challenging intake scenarios for a high specific speed pump. For a conventional bellmouth intake to function correctly, it must be positioned close to a back wall, with well-conditioned approach flow at controlled velocities and trajectories. In this application, these conditions could not be achieved.

As a result, a Bellmouth solution was discounted. Instead, the design team developed a Formed Suction Intake (FSI) that could be accommodated within the existing gravity channel.

The FSI was engineered to normalise incoming flow into a uniform, steady, and swirl-free profile, even under adverse conditions such as:

- Flow passing over the pump intake

- Crossflow within the channel

- Skewed or non-uniform velocity distributions

This approach enabled reliable pump operation without compromising the existing civil structure.

The FSI is designed to normalise incoming flow into a uniform, steady, and swirl-free profile, even in the event of: Flowing water passing over the pump intake, crossflow conditions or skewed velocity distributions at the entrance.

Case Study 2 – Inlet Sump without Flow Splitters

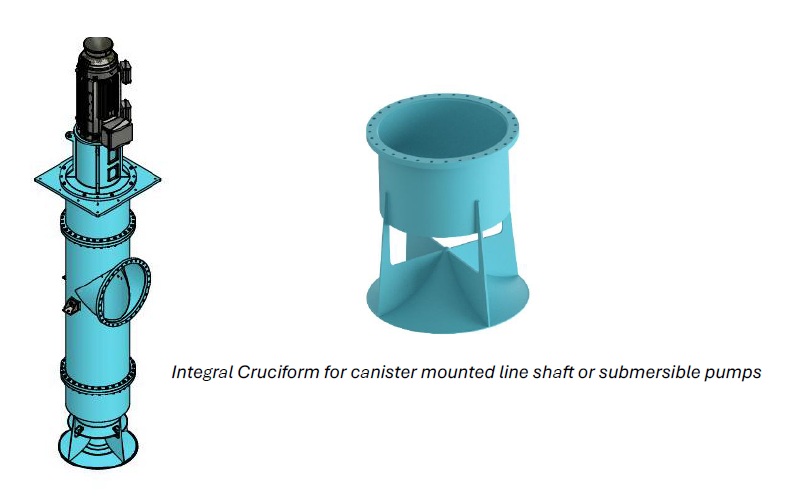

For high specific speed pumps operating in open intakes or sumps, it is generally recommended to incorporate a flow splitter or cruciform beneath the bellmouth. The primary function of this component is to act as a flow straightener, mitigating pre-swirl before the flow enters the impeller.

Pre-swirl has a significant impact on rotodynamic pump performance:

- Co-rotating pre-swirl (same direction as the impeller):

- Reduces effective head and input power

- Decreases delivered flow rate

- Counter-rotating pre-swirl (opposite direction to the impeller):

- Increases developed head

- Causes a substantial reduction in efficiency

- Can lead to excessive absorbed power, instability, and potential driver overload

Pumpflow Ltd was contracted to supply retrofit high specific speed pumps for an existing flood control pumping station. Inspection revealed that the intake structure lacked any form of baffling or flow straightening. Given the critical nature of the installation, the pumping station was required to remain operational throughout the works.

Pumpflow’s solution was to integrate suspended cruciform flow straighteners directly onto the pump canisters. This approach allowed effective flow conditioning to be installed without isolating or draining the intake structure, thereby maintaining continuous operation while saving both time and cost.

Conclusion

High capacity, low-lift pumps demand careful consideration of intake hydraulics. While ideal intake conditions are rarely achievable in existing installations, well-engineered flow conditioning solutions can significantly improve performance, reliability, and service life.

Pumpflow Ltd brings decades of experience in hydraulic intake design and flow conditioning and rectification measures. If you have a challenging intake application or require retrofit solutions, please do not hesitate to contact us.